Renewable Energy for Southeast Georgia

Where Innovation Meets Energy -

Altamaha Green Energy

Altamaha Green Energy (AGE) is a renewable power generation facility that will produce clean, reliable energy from forestry byproducts to help meet Southeast Georgia’s future electricity needs.

AGE represents a significant investment in our community’s economy and workforce—and supports a healthy market for renewable forestry and American manufacturing.

By strengthening the local economy, enhancing Georgia’s electricity infrastructure, and expanding the state’s renewable energy mix, Altamaha Green Energy advances American energy independence—powered by local resources and built for future generations. It’s a project that delivers long-term value for Jesup and a cleaner, more reliable electricity supply for the region.

Get The Facts

Georgia faces real-world energy challenges—and Altamaha Green Energy is part of the solution.

This project puts local resources to work, strengthens our forestry economy, and supports reliable, renewable power for Southeast Georgia. Homegrown, renewable energy like AGE isn’t just good policy—it’s long-term thinking in action. It reflects a commitment to building local opportunity, increasing American energy dominance, and using what Georgia already has to power local homes, schools and businesses.

70 MW

of Renewable

Electricity

35,000

Homes Powered

by Age Annually

130 Tons

Reduction in Air Emissions

Particulate Matter Locally

Energy for Our Community

This project means more than renewable power—it means reliable energy for tens of thousands of nearby homes, real economic opportunity for South Georgia, and long-term benefits for communities across Wayne County and beyond. Cleaner air, stronger infrastructure, and a homegrown energy solution—all starting right here in Jesup.

Renewable Local Energy

Altamaha Green Energy will generate reliable, renewable power using responsibly sourced forest byproducts—helping to diversify Georgia’s energy supply while supporting the region’s forestry economy.

A Boost for Southeast Georgia

This project will strengthen the local economy, support rural infrastructure, and contribute to long-term economic growth across Wayne County and surrounding areas.

Supporting American Energy Dominance

By using homegrown resources to produce power here in Georgia, AGE helps reduce reliance on foreign energy and keeps investment rooted in American communities.

A Smarter Use of Resources

Altamaha Green Energy puts leftover forest materials to work—generating reliable, renewable energy from resources that would otherwise go unused—without the need for new land clearing or changes to how forests are managed. It’s a win-win that supports working forests and the communities around them.

Questions & Answers

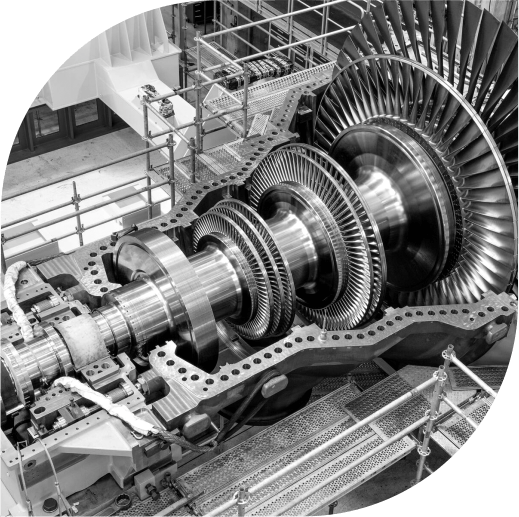

What type of technology will AGE use to generate renewable energy?

Altamaha Green Energy will use Circulating Fluidized Bed (CFB) technology—a proven and efficient method for converting biomass into electricity. Unlike older systems, CFB technology can efficiently handle materials that have been historically considered forestry waste because they contain sand or grit that would damage traditional systems. This innovation makes it possible to put forestry leftovers to productive use in a controlled setting—rather than burning them in open fields.

AGE’s high-tech system enables efficient energy recovery and strong emissions control, making it a dependable choice for adding renewable power to Southeast Georgia’s electric grid.

What is biomass?

Biomass refers to natural materials from plants or trees that can be used to generate renewable energy. AGE will use responsibly sourced residual materials, including leftover limbs, branches, bark, storm debris, and lower-value or damaged trees unsuitable for other uses.

Today, most of the timber harvest waste byproducts (tree tops, branches, pine cones) aren’t collected—they’re either pushed into piles and burned in the open field or left on the ground, where they break down and release methane, a potent greenhouse gas.

The U.S. Department of Energy classifies this type of biomass used for fuel as a renewable, carbon-neutral source of energy that can generate electricity around the clock, similar to traditional power stations.

How does the AGE project benefit local forest landowners and help sustain Georgia’s forests?

AGE will partner directly with local landowners to collect leftover woody debris—such as limbs, tops, and branches—after timber harvests. By providing this cleanup service, AGE will significantly reduce the landowners’ costs and accelerate the replanting and regeneration process.

This economically beneficial partnership will encourage landowners to maintain their land as productive forests rather than converting it to other uses like development or agriculture. Ultimately, AGE’s approach promotes healthy, sustainable forest management and strengthens Georgia’s forestry economy, benefiting both landowners and the broader community.

What happens to biomass if it’s not used to create renewable energy?

If not put to good use, these materials from forestry operations are often burned in the field, releasing emissions in a non-controlled setting, or left to break down naturally—releasing methane, a greenhouse gas, in the process. Altamaha Green Energy gives these byproducts a productive second life by turning them into electricity, reducing waste and capturing value from resources already available in Georgia.

Does biomass help reduce fossil fuel dependence?

Yes. AGE produces 70 megawatts of renewable baseload power—electricity that’s available when it’s needed, day or night. It complements solar and wind energy, which can be weather-dependent, and helps make Georgia’s power grid more reliable and self-sufficient.

How will the project affect air quality and the environment?

Altamaha Green Energy will help improve local air quality by reducing airborne particle emissions by nearly 130 tons each year. In addition, the facility offers a cleaner alternative to the long-standing practice of burning leftover forestry debris—like branches and bark—in open fields, which releases smoke and particulates directly into the air. Instead, AGE processes these materials in a controlled setting using advanced systems—including scrubbers—that are specifically designed to capture and reduce emissions. It’s a smarter way to manage forestry byproducts while helping protect the air we all share.

The facility is designed to meet or do better than all state and federal environmental standards, operating responsibly with modern safeguards to protect air quality and the surrounding environment.

What older equipment will AGE replace?

AGE will permanently shut down RYAM’s outdated No. 3 Power Boiler—replacing it with a cleaner, more efficient system. The new CFB boiler features modern pollution controls designed to reduce emissions and improve air quality. It’s a major upgrade that supports cleaner air for the community.

Are there health protections in place for the public?

Yes. Independent modeling confirms that projected emissions are well below state health risk thresholds. AGE’s system includes advanced pollution controls—like scrubbers and baghouses—that capture and filter emissions before they leave the stack. The project also consolidates emissions from older equipment into a single, highly controlled system.

How does biomass compare to fossil fuel power generation?

Biomass and fossil fuels like coal may both release carbon dioxide when used for energy—but where that carbon comes from, and what happens to it afterward, makes all the difference.

Coal is dug from underground and releases carbon that has been stored for millions of years. Once it’s burned, that carbon enters the atmosphere with no natural process to remove it on the same timescale. This is how fossil fuels add new carbon to the environment.

Biomass works differently. The materials used—bark, limbs, wood chips—come from trees that were harvested as part of regular forestry operations, where growth and regrowth are continually managed over time. As trees grow, they absorb carbon dioxide from the air. When this wood is later used for energy, the carbon released is part of a natural cycle. Forests that are replanted and allowed to grow continue to absorb that carbon from the atmosphere.

This closed-loop process means the carbon released during energy generation can be offset by the carbon absorbed through ongoing forest growth. It’s not just about what comes out of the facility—it’s about the full life cycle of the material.

At Altamaha Green Energy, we’re using existing forestry leftovers—materials already in the natural cycle. This approach doesn’t introduce new carbon. It puts available resources to work in a system that’s efficient, accountable, and built to meet strict environmental standards.

Why was this project started—and where did the idea come from?

This project began with a public, competitive process led by Georgia Power, which called for new sources of renewable energy to help diversify Georgia’s energy supply.

Altamaha Green Energy was proposed and selected through that process, competing successfully against other proposals. The result is a locally driven project that supports Georgia’s long-term energy needs using existing natural resources.

ARE YOU USING THE BEST AVAILABLE TECHNOLOGY TO CONTROL EMISSIONS?

Yes.

AGE is committed to responsible environmental stewardship and voluntarily incorporated advanced emissions-control technologies in the design of the new facility. These are the same controls that would be required by a Best Available Control Technology (BACT) analysis if the facility were subject to Prevention of Significant Deterioration (PSD) permitting. They will also ensure we meet other stringent federal and state regulations such as Maximum Achievable Control Technology (MACT) standards.

These advanced technologies include:

- Circulating Fluidized Bed (CFB) Boiler: An advanced, highly efficient combustion system designed specifically for clean burning of biomass materials, substantially reducing emissions compared to traditional boilers. This represents a significant technological upgrade over RYAM’s older Power Boiler #3, which will be retired.

- High-Efficiency Fabric Filter (Baghouse): Captures particulate matter effectively, including PM, PM10, and PM2.5, significantly reducing airborne particles and improving local air quality.

- State-of-the-Art Sorbent Injection System (Dry Scrubber): Designed to remove and reduce emissions of pollutants such as SO₂, acid gases, and other hazardous air pollutants, ensuring strict compliance with federal Maximum Achievable Control Technology (MACT) standards. The dry scrubber technology also reduces water usage and wastewater generation.

- Selective Non-Catalytic Reduction (SNCR): Reduces emissions of nitrogen oxides (NOx) by breaking them down to nitrogen, carbon dioxide, and water vapor.

- Continuous Emissions Monitoring Systems (CEMS): Real-time emissions monitoring equipment installed to ensure ongoing compliance and immediate response to emission fluctuations.

These integrated measures ensure AGE employs some of the most advanced and environmentally responsible emissions-control technologies available today.